Why?

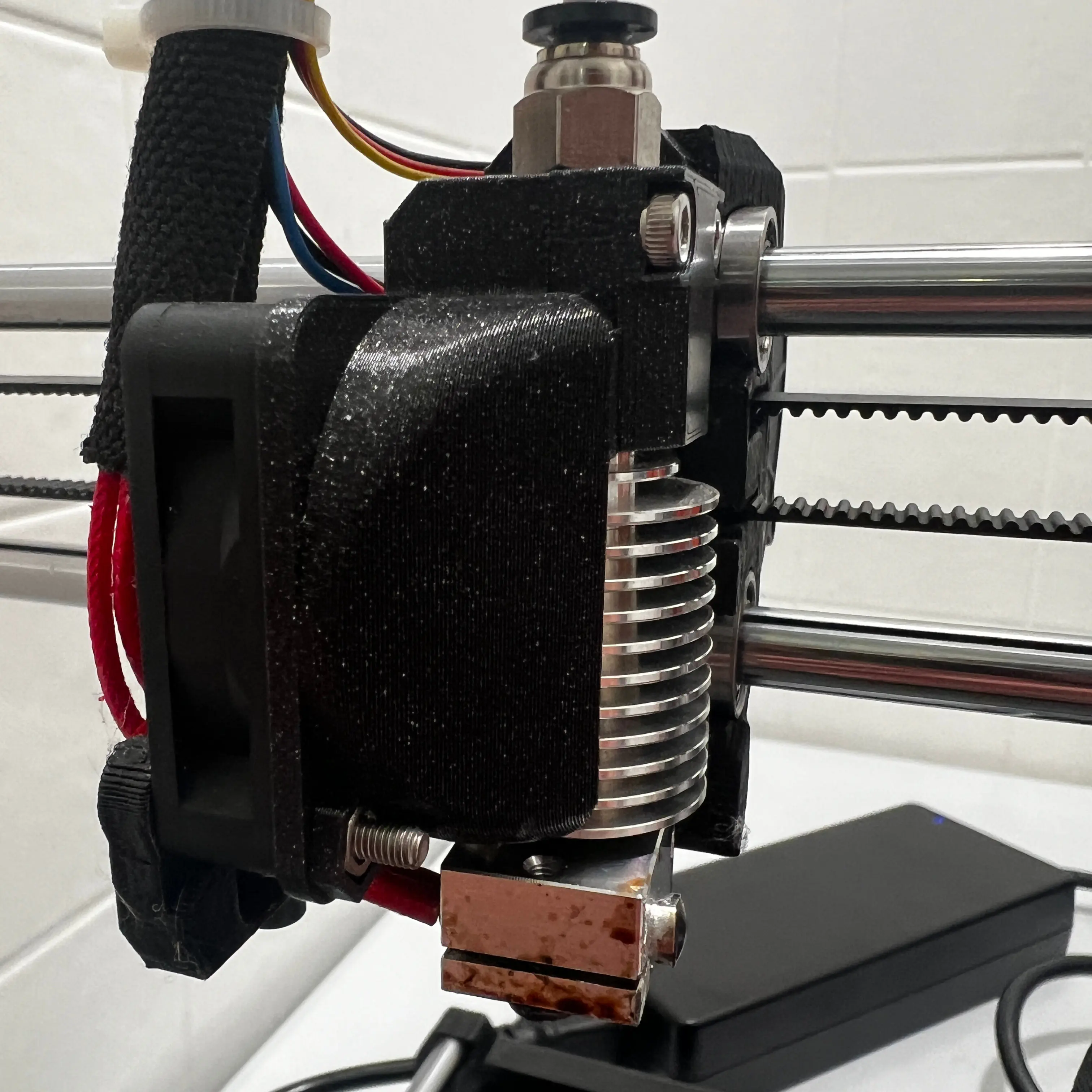

The most common hotend design is the V6 hotend, and many hotends are built using that same shape and mounting.

My printer doesn’t support V6 hotends normally, so I made my own adapter.

The Design

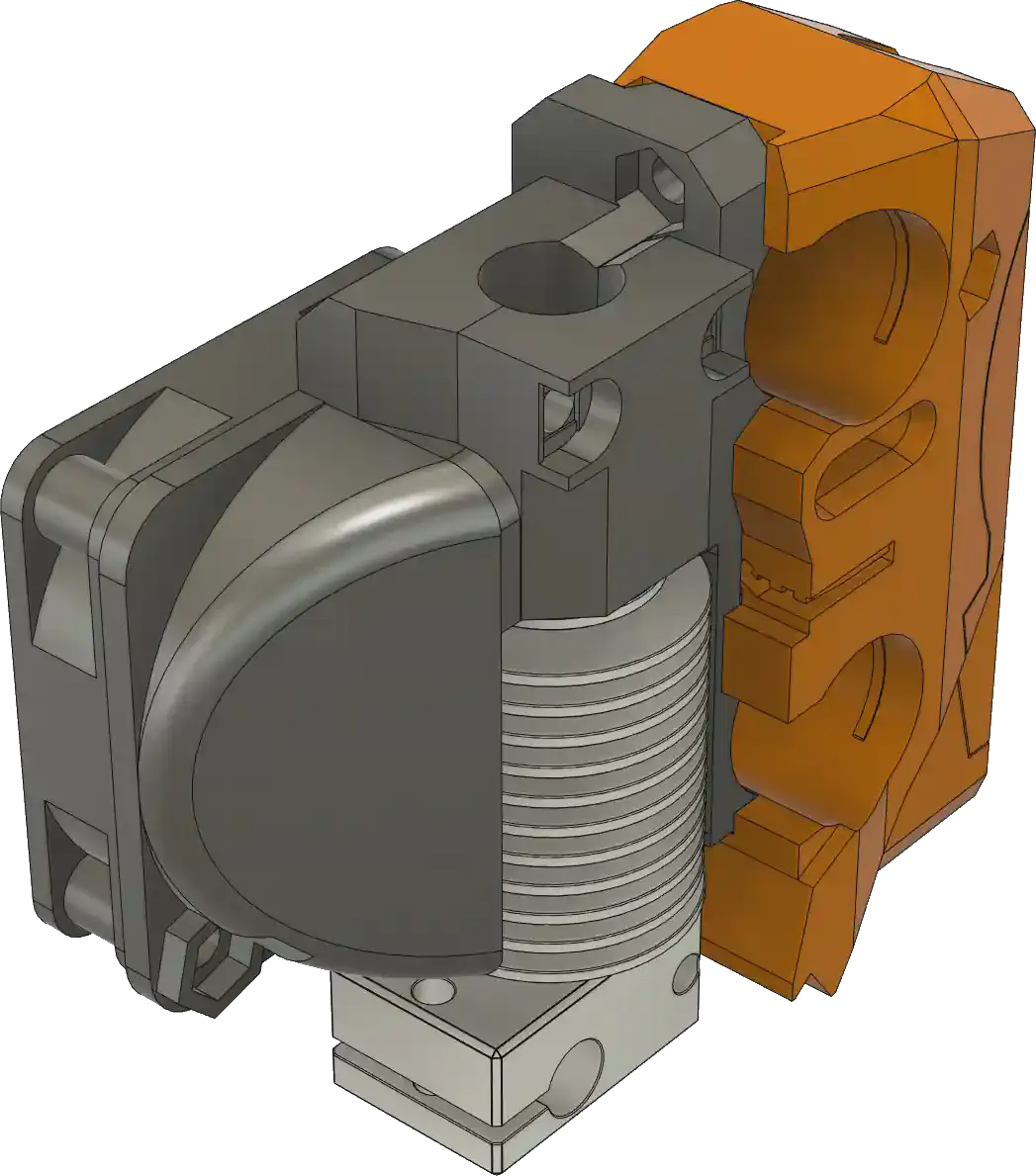

The design was based on a few other designs that I imported into the model.

This included:

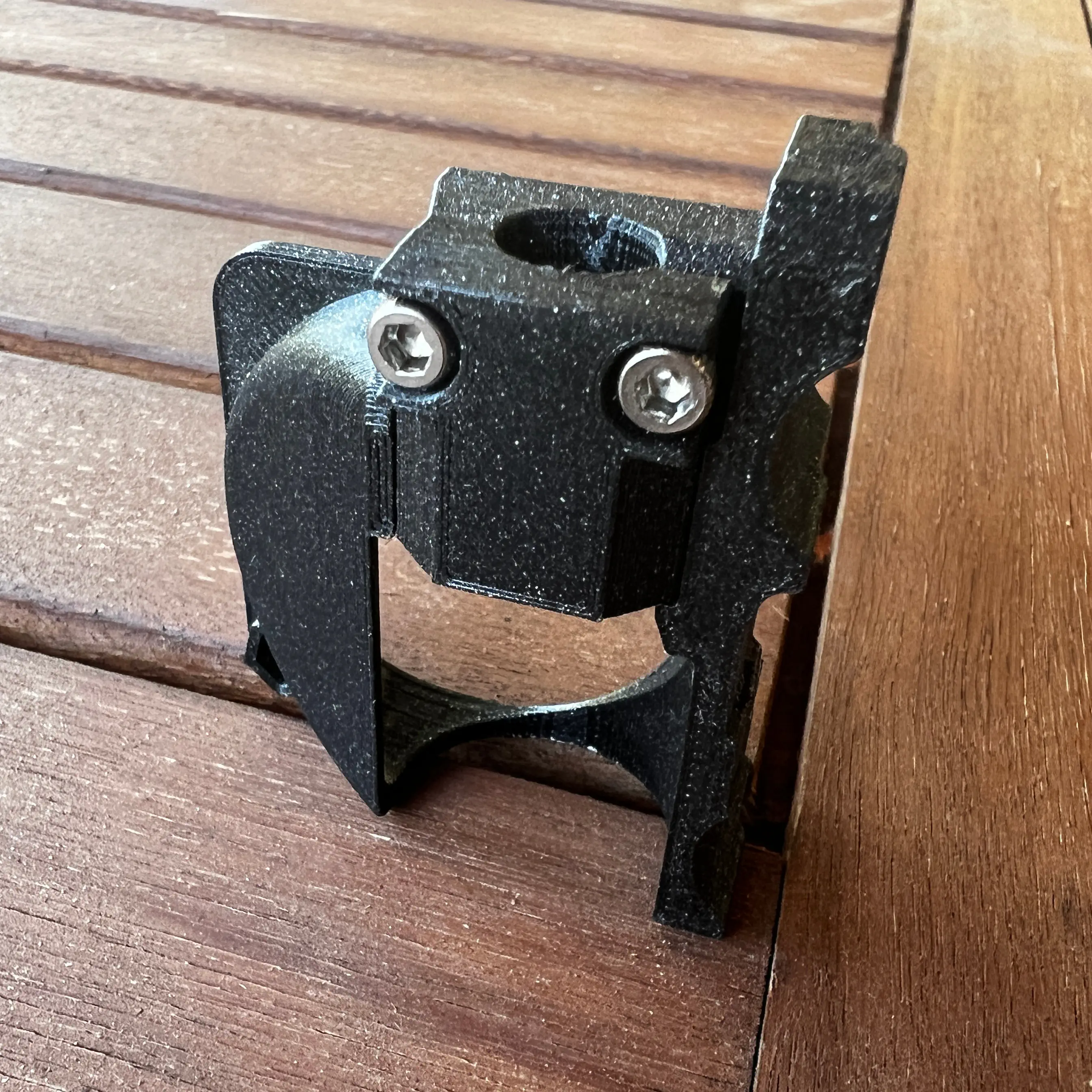

- The X-carriage that holds the bearings and moves on the X-axis

- The fan

- The hotend

- The position of the previous hotend, so the nozzle position does not change.

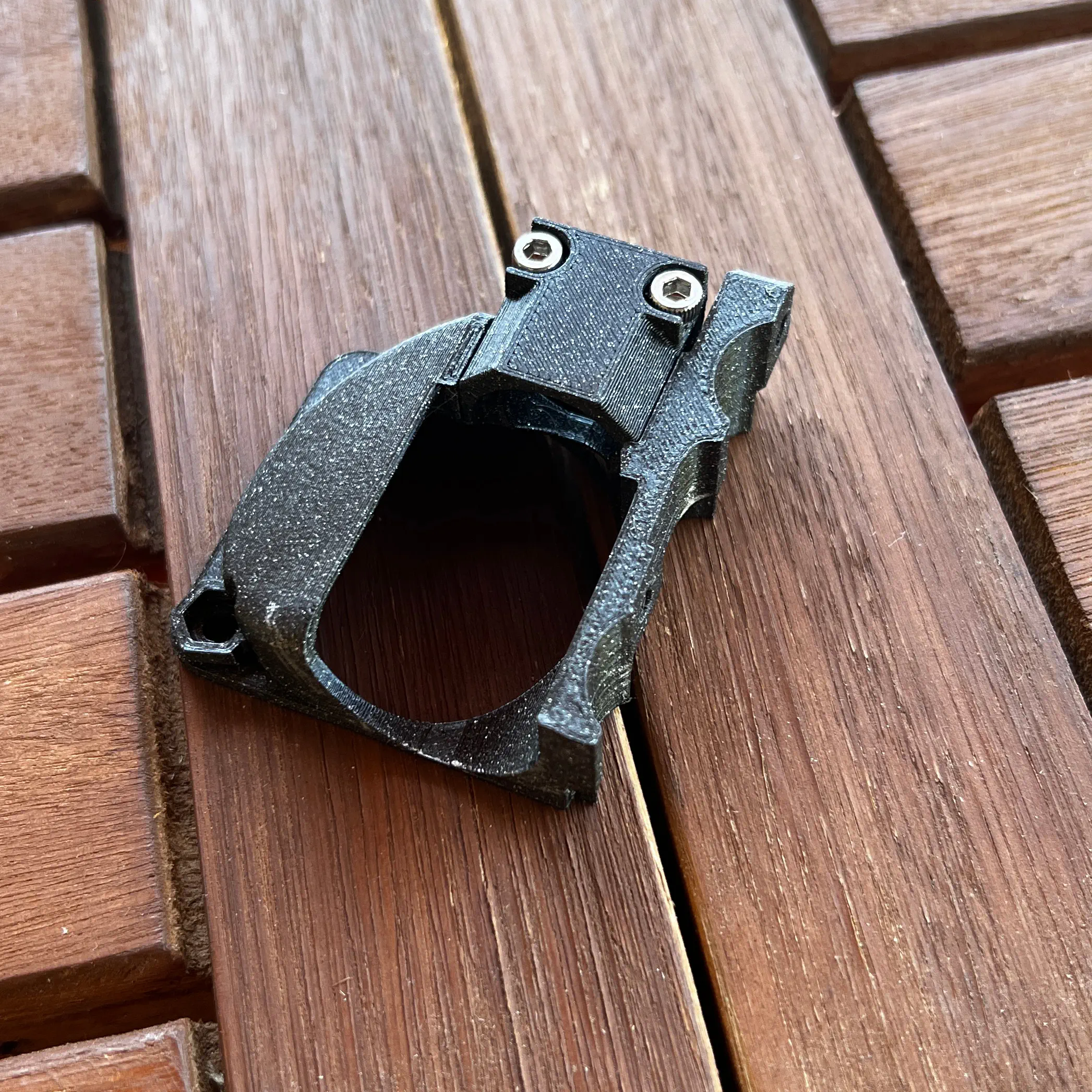

The hotend is held in place using 2 screws that sandwich the top of the hotend.

The fan blows on the hotend to prevent heat creep.

The design went through 5 iterations.

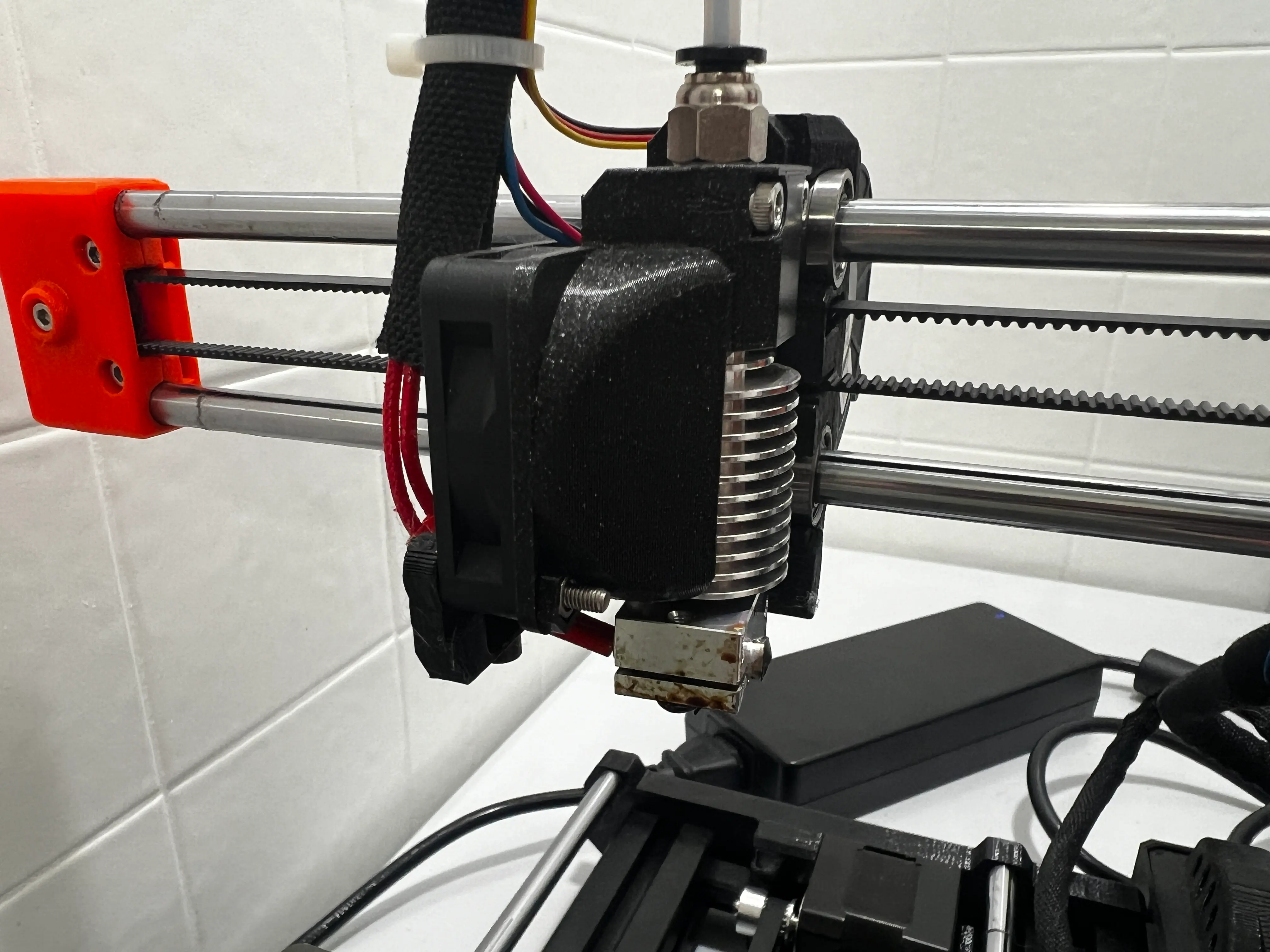

The Result

My Thoughts

This is one of my more successful designs. There is nothing about the design that I think needs to be revised, and it has worked perfectly so far.